Safety inspections and risk assessments are essential components of workplace safety, ensuring that potential hazards are identified, managed, and mitigated. Whether in construction, manufacturing, or office environments, conducting thorough inspections and assessments helps maintain compliance with safety regulations and creates a safer environment for employees, visitors, and contractors. In this blog, we’ll explore the importance of these processes and how they contribute to accident prevention and overall safety in the workplace.

What Are Safety Inspections?

Safety inspections involve a detailed examination of a workplace, equipment, or processes to ensure they comply with safety standards. These inspections aim to identify potential hazards that could result in accidents or injuries. Regular safety inspections are crucial to maintaining a safe environment and preventing harm to workers.

Key Elements of a Safety Inspection:

- Workplace Layout: Ensuring that the design and layout of the worksite support safety, with clear walkways and proper equipment placement.

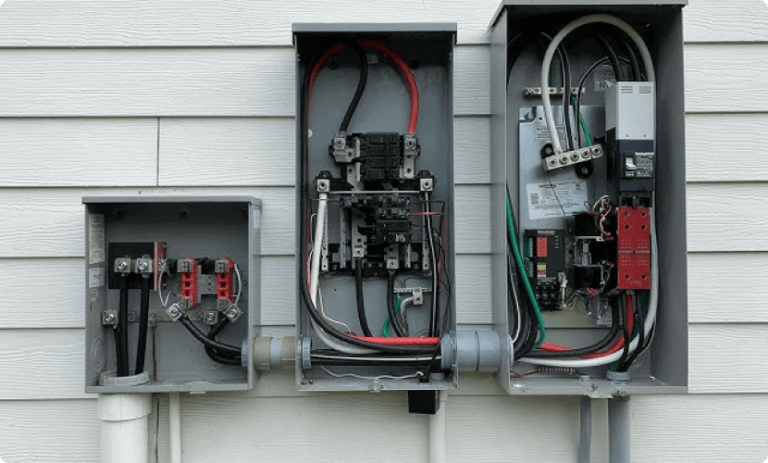

- Equipment Condition: Checking machinery and tools for proper functioning, wear and tear, and ensuring they are being used according to safety protocols.

- Hazardous Materials: Identifying and handling hazardous substances safely, including proper storage, labelling, and disposal methods.

What Are Risk Assessments?

A risk assessment is a systematic process to evaluate potential hazards and assess the risk they pose to employees or others. The assessment involves identifying hazards, analysing their potential impact, and determining the likelihood of an occurrence. After identifying risks, control measures are put in place to either eliminate the hazard or reduce the associated risks to an acceptable level.

Steps in a Risk Assessment:

- Identify Hazards: Identify anything that could potentially cause harm. This can include physical hazards, chemical exposure, ergonomic risks, or biological threats.

- Evaluate Risks: Assess how likely it is for each hazard to cause harm and how severe the harm could be. This involves looking at both the frequency and potential severity of incidents.

- Control Measures: Decide on actions to eliminate or mitigate risks. This can include installing safety barriers, providing personal protective equipment (PPE), or redesigning work processes.

- Review and Update: Risk assessments must be reviewed regularly, especially when new equipment is introduced or processes change. Keeping assessments current is key to maintaining safety.

Why Are Safety Inspections and Risk Assessments Important?

1. Compliance with Regulations

In Australia, workplace safety is governed by strict regulations such as those outlined in the Work Health and Safety (WHS) Act. Conducting regular inspections and assessments helps organisations stay compliant with these laws and avoid costly fines or legal issues.

2. Prevention of Accidents

Proactive safety inspections and risk assessments help to identify hazards before they lead to accidents. This helps reduce the likelihood of injuries, fatalities, and property damage in the workplace.

3. Cost Savings

Preventing accidents not only protects employees but also saves businesses money by reducing downtime, minimising workers’ compensation claims, and lowering insurance premiums. Investing in safety pays off in the long run.

4. Improved Workplace Morale

A safe workplace fosters trust and confidence among employees. When workers feel that their safety is a priority, they are more likely to be engaged, productive, and loyal to the company.

Best Practices for Conducting Safety Inspections and Risk Assessments

- Involve Employees: Encourage workers to participate in safety inspections and risk assessments. They are often the best source of information about hazards they encounter daily.

- Use Checklists: Create comprehensive safety checklists for inspections to ensure that no area or equipment is overlooked.

- Prioritise High-Risk Areas: Focus on areas with the highest potential for danger, such as those involving heavy machinery, hazardous materials, or high-traffic zones.

- Document Everything: Keep detailed records of inspections, assessments, and any corrective actions taken. Documentation is vital for compliance and tracking safety improvements over time.

- Continuous Improvement: Regularly review and improve safety procedures. As workplaces evolve, so should the safety measures to ensure ongoing protection.

Contact us

Safety inspections and risk assessments are critical for maintaining a secure and compliant workplace. By identifying hazards and implementing effective controls, businesses can significantly reduce the risk of accidents and injuries. Prioritising safety not only protects employees but also enhances productivity and supports long-term success.