In today’s rapidly evolving electrical industry, professionals are constantly seeking innovative, reliable, and safe solutions to meet growing demands. One of the most advanced and efficient solutions in this field is Cross-Linked Polyethylene (XLPE) cabling. Its exceptional durability, thermal resistance, and flexibility have made it the go-to choice for electricians across Australia.

What is XLPE Cabling?

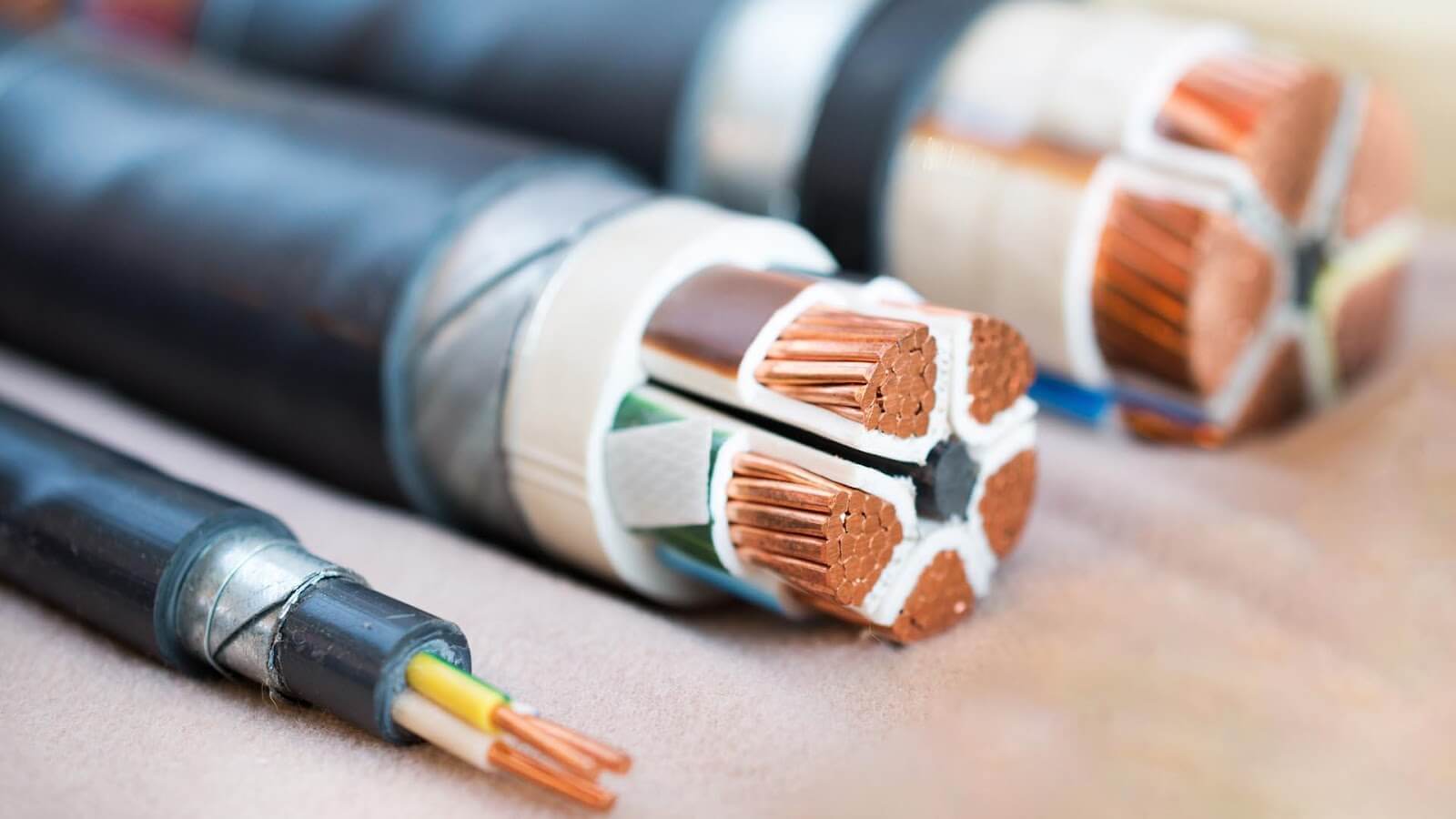

XLPE (Cross-Linked Polyethylene) cables are made from a high-quality plastic polymer that has been chemically altered to form cross-links between the molecules. This process enhances the properties of polyethylene, improving its performance under high-stress conditions. XLPE cables are widely used in both underground and overhead installations, making them highly versatile for numerous applications in the electrical industry.

Advantages of XLPE Cabling

One of the standout advantages of XLPE cables is their ability to withstand extreme temperatures. This quality is essential for applications that require continuous exposure to heat, such as industrial plants or high-voltage power distribution systems. XLPE cables can operate efficiently at temperatures up to 90°C and withstand short-term peaks of up to 250°C. This makes them more reliable than traditional PVC cables, which have lower thermal limits.

In addition to its thermal resistance, XLPE cabling offers excellent resistance to chemicals and water, which is critical in industries such as mining, oil, and gas. Unlike traditional insulation materials, XLPE is not prone to moisture absorption, significantly reducing the risk of corrosion and ensuring long-term durability. Its chemical resistance also makes it ideal for environments where cables might come into contact with oils, acids, or other corrosive materials.

Another benefit of XLPE cables is their enhanced flexibility. Electricians find it easier to work with XLPE cables due to their manageable weight and bendability, especially in confined spaces. This flexibility speeds up installation and allows for more intricate cable layouts. Additionally, its robustness ensures that it can withstand mechanical stress during installation without compromising its integrity.

Applications of XLPE Cabling in Australia

In Australia, XLPE cables are extensively used in a variety of applications. Whether it’s for industrial facilities, commercial buildings, or infrastructure projects, XLPE has become a reliable choice. With the increasing demand for renewable energy sources such as solar and wind, XLPE cables are being used for transmitting power from these sources due to their ability to handle high voltage and harsh environmental conditions.

For underground power distribution, XLPE cables are preferred due to their superior insulation properties, which reduce the likelihood of short circuits and other electrical faults. XLPE’s resilience against environmental factors, such as water ingress and chemical exposure, further strengthens its role in providing reliable underground electrical connections.

The Future of XLPE Cabling

As industries and urban environments continue to grow, the demand for reliable, safe, and efficient power distribution methods will rise. XLPE cables are at the forefront of this shift, offering not only a solution for today’s needs but also promising future benefits. Its environmentally friendly characteristics, such as reduced smoke emissions in the event of a fire, are increasingly vital in meeting safety regulations.